2. Power and Energy Monitoring and Control

by Admin

Posted on 26-07-2022 09:03 AM

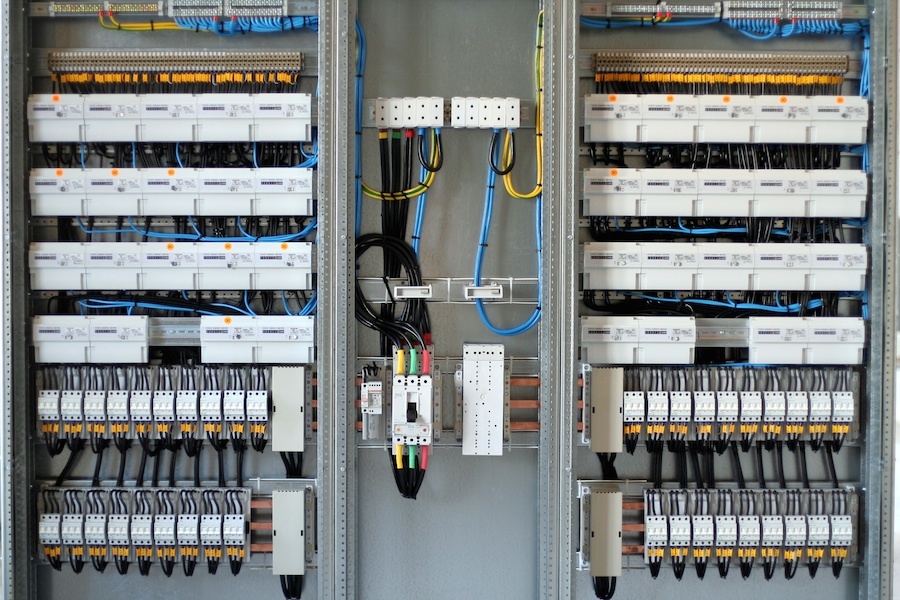

Main circuit breaker. This is like the disconnect of the main electrical panel leading into a home or office. Main circuit breakers handle between 120v–480v in most industrial applications.

Surge arresters. This component prevents lightning strikes or utility power surges from damaging the electrical components inside the panel due to overvoltage. Transformers. Depending on the incoming voltage, transformers may reduce voltage to 120v for various components or step down voltage to 24v in instances where incoming power is 120v. Terminal blocks. These blocks help to organize and distribute the array of wires coming from various sources to different electrical devices.

Surge arresters. This component prevents lightning strikes or utility power surges from damaging the electrical components inside the panel due to overvoltage. Transformers. Depending on the incoming voltage, transformers may reduce voltage to 120v for various components or step down voltage to 24v in instances where incoming power is 120v. Terminal blocks. These blocks help to organize and distribute the array of wires coming from various sources to different electrical devices.

Main circuit breaker: manages the power outlet, it will cut the circuit if there is an electrical overload or a short-circuit surge arresters: prevents lightning strikes, highly effective for electrical control panels located outside or on the roof. Terminal blocks: organises and distributes wires coming from different electrical devices. Electricity is a common hazard especially to those businesses which rely on it to operate. Regular maintenance and safety checks must be carried out for everyone’s safety. Best practises include: clear & correctly labelled components, terminals and wiring pest control - especially in underfloor wiring monitoring & assessing the condition of electrical components i.

Intelligent motor control centres are the latest generation mccs which allow the user to access the data from the intelligent devices within the mcc by connecting to any network level such as ethernet. This feature gives the ability for monitoring and diagnostics of the mcc from a maintenance pc or even a scada system. An intelligent mcc can also give the user live and historical energy usage data allowing them to optimise their plant and processes. For an intelligent mcc, every unit must have communication capability. This is necessary in order to replace the conventional control inter-wiring with a single communication wire.

Mimic panels typical panel variations automatic mains / generator supply source changeover panels: these incorporate schneider electric or equal electronic controllers to effect supply changeover. Manual supply changeover panels: these incorporate manually operated socomec or equal changeover switches. Automatic transfer switch panels: these incorporate asco or equal changeover switches. Functional units: the panels can be designed to include all types of devices such as mccbs, mcbs, fuse switches and motor starters. Control and monitoring: design and installation of janitza digital integrated measuring systems for energy distribution and energy optimisation. Construction: wardrobe or cubicle type.

3. Power Distribution Systems

Supplying products since the 1970’s, lintott has comprehensive expertise in control panel design, manufacture, testing, commissioning & aftercare, across a plethora of applications & sectors.

Standard & bespoke low voltage motor control centres (conventional, intelligent & withdrawable), power distribution & process control systems. Lintott provides the complete automation & digital integration package, produced & supported by one source.

Standard & bespoke low voltage motor control centres (conventional, intelligent & withdrawable), power distribution & process control systems. Lintott provides the complete automation & digital integration package, produced & supported by one source.

We have been building panels now for over 30 years both for our own solutions and for our clients. We are experienced in the design and build of a wide range of control panels including, plc / dcs cabinets, power distribution panels, server cabinets and remote io panels. We also have substantial experience in the design and build of panels for hazardous areas and work in conjunction with various certifying bodies to deliver a solution that meets your hazardous area requirements. Uniquely we can also provide full automation and control services from our systems and technology team adding full consultation, design build and test of state-of-the-art control systems.